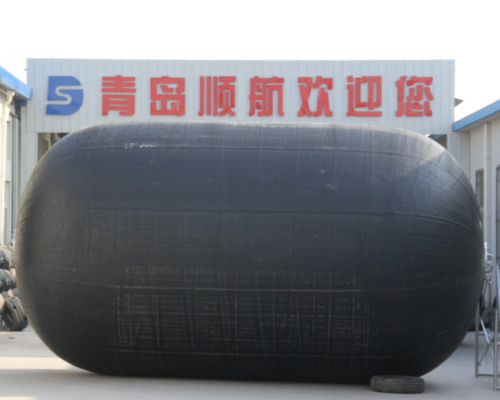

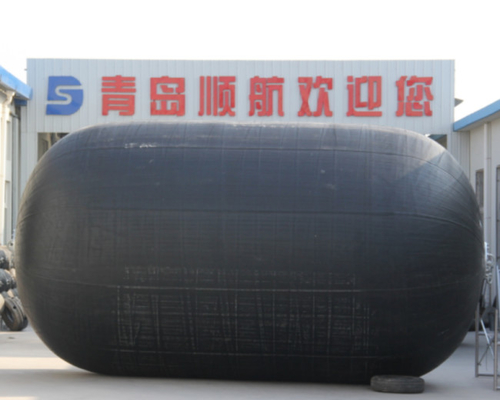

Yokohama Sling Type Marine Rubber Fenders

Product Introduction

Yokohama rubber fenders are used world wide for ship-to-ship (STS) transfer operations, terminals, and for all kinds of ships. Since its creation until today, more than millions of fenders have been supplied worldwide both for ship-to-ship and ship-to-dock (STD) operations serving our valuable customers. These fenders play a critical role in the safe operation of ship berthing and mooring.

The Advantages of the Marine Rubber Fenders:

1. Guaranteed energy absorption

2. Thick skin construction

3. Good angular performance

4. Less surface pressure onto the side wall of ships. (The capability of accepting surface pressure of the fender is up to 14 ton/m2).

5. No reduction on the performance of compression when inclined.

6. Especially in mooring of large scale ships in sea docks and lightering.

Our Advantages

1 Safety and Reliability

Shunhang Pneumatic Rubber Fenders are constructed of natural rubber, several layers of strong tire-cord, and are thus resistant to pressure and cutting. The safety factor adopted in the design of this fender is based on accepted theory and has been proven by extensive experimentation.

2 Patented Active Protecting Safety Valve Design

All Shunhang Pneumatic Rubber Fenders are equipped with a safety valve to release the inside air in the event of accidental over-pressure.

3 No Deterioration or Variation in Performance

Shunahng Pneumatic Rubber Fenders utilize the compressive elasticity of air, therefore performance deterioration due to fatigue is absent.

Marine rubber fender types are defined as follows:

1. Type I — Net-type;

2. Type I Single — Net-type and one end with no flange opening and no metal parts.

3. Type II — Sling-type.

Type requirements:

1. Type I and Type I Single (Net-type) fenders shall be covered by a chain net, wire net, or fibre net. Each end of longitudinal chains, wires, or fibres shall be linked together with one or two ring(s), which shall be connected with a guy-chain or guy-rope. Usually, these nets will be fitted with used tyres or rubber sleeves to provide additional protection to the fender body.

2. Type II (Sling-type) fenders shall have a lifting device on each end, which shall be connected with a guy-chain or guy-rope.

Specificaton of Marine Rubber Fender

| Size |

Initial Internal Pressure 50kPa |

Initial Internal Pressure 50kPa |

|

Diameter/

Meter

|

Length

/Meter

|

Energy Absorption /KJ |

Reaction Force /KN |

Energy Absorption /KJ |

Reaction Force /KN |

| 0.5 |

1 |

6 |

64 |

8 |

85 |

| 0.7 |

1.5 |

17 |

137 |

24 |

180 |

| 1.0 |

1.5 |

32 |

182 |

45 |

239 |

| 1.0 |

2.0 |

45 |

257 |

63 |

338 |

| 1.2 |

2.0 |

63 |

297 |

88 |

390 |

| 1.5 |

3.0 |

153 |

579 |

214 |

761 |

| 1.7 |

3.0 |

191 |

639 |

267 |

840 |

| 2.0 |

3.5 |

308 |

875 |

430 |

1150 |

| 2.5 |

4.0 |

663 |

1381 |

925 |

1815 |

| 2.5 |

5.5 |

943 |

2019 |

1317 |

2653 |

| 3.0 |

5.0 |

1050 |

2000 |

1571 |

2709 |

| 3.0 |

6.0 |

1312 |

2488 |

1888 |

3292 |

| 3.3 |

4.5 |

1175 |

1884 |

1640 |

2476 |

| 3.3 |

6.0 |

1675 |

2783 |

2338 |

3652 |

| 3.3 |

6.5 |

1814 |

3015 |

2532 |

3961 |

Outer and Inner Rubber Material Requirements of Marine Rubber Fenders

|

Test item

|

Test method

|

Required value |

| Outer rubber |

Inner rubber |

| 1. Before aging |

– |

– |

– |

| 1.1 Tensile strength |

ISO 37:2011 |

18 MPa or more |

10 MPa or more |

| 1.2 Elongation |

ISO 37:2011 |

400 % or more |

400 % or more |

| 1.3 Hardness |

ISO 7619-1:2010 |

60 ± 10 (Durometer hardness

Type A)

|

50 ± 10 (Durometer hardness

Type A)

|

|

2. After aging

|

ISO 188:2011

|

Air oven aging, 70°C ± 1°C,

96 h

|

Air oven aging, 70°C ± 1°C,

96 h

|

| 2.1 Tensile strength |

ISO 37:2011 |

Not less than 80 % of the original

property

|

Not less than 80 % of the origi-

nal property

|

| 2.2 Elongation |

ISO 37:2011 |

Not less than 80 % of the original

property

|

Not less than 80 % of the origi-

nal property

|

| 2.3 Hardness |

ISO 7619-1:2010 |

Not to exceed the original prop-

erty by more than 8

|

Not to exceed the original prop-

erty by more than 8

|

| 3. Tear |

ISO 34-1:2010 |

400 N/cm or more |

No requirement |

| 4. Compression set |

ISO 815-1:2008 |

30 %(70 ± 1 °C, 22hours) or less |

No requirement |

|

5. Static ozone aging

test

|

ISO 1431-1:2012

|

No cracks after elongation by 20 % and exposure to 50 pphma at 40 °C for 96 h |

No requirement

|

|

NOTE If the colour of the outer cover is not black, the material requirements will differ from those in this table.

a Parts of ozone per hundred million of air by volume.

|

Notice Of Fender Application And Storage

1. The fender pressure should be kept in the standard pressure ,within the rate of ± 5% range.

2. Often check the pressure , when the pressure drops, Inflate the fender in time, so as not to affect the normal use of the fender.

3. When connecting the fender with a steel wire rope, the wire rope should be fitted with a rubber sleeve to avoid damage to the fender

4. Do not touch the fender surface with the the sharp objects , to prevent piercing the fender. If the fender's surface is damaged, it will affect the lifespan of the fender.

5. When the fender is in normal use, the fixing points should be firm, prevent the detachment and wash away the fender. Suspension of the rope and hook ring should be connected orderly , can’t be in a mess.

6. If the fender won’t be used in a long time , to clean the fender surface with fresh water, and place the fender in a dry, cool, ventilated place, without direct sunshine.

7. When the fender is stored for a long time, the pressure should be reduced and the fender should be placed far away from the heat source.

8. Because the fender is rubber product, should try to avoid the fireworks, not contact with acid, alkali, oil and other organic solution

9. When the fender is stored, it shall not be folded or stacked, and don’t stack other objects on the fender.

FAQ:

Q1: What's your MOQ?

Answer: The MOQ of our marine rubber fender is 1pc.

Q2: What's the lifespan of your marine rubber fenders?

Answer: Designed lifespan of our marine rubber fenders is 6 to 10 years

Q3: What's your warranty period?

Answer: Our warranty period is 2 years. we will responsible for the repairment or replace the new ones for you if it proved to be our quality problem.

Q4: Can you suggest the suitable marine rubber fenders size and quantity for me?

Answer: Pls tell us your ship information, as experienced manufacturer, we can suggest suitable size and quantity for you.

Q5: What kind certificate you can provide.

Answer: CCS,RS, SGS etc.certificate is available

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!